Your Gold smelting flux formula images are available. Gold smelting flux formula are a topic that is being searched for and liked by netizens today. You can Get the Gold smelting flux formula files here. Download all free photos and vectors.

If you’re looking for gold smelting flux formula images information connected with to the gold smelting flux formula keyword, you have pay a visit to the ideal site. Our site frequently gives you suggestions for downloading the highest quality video and image content, please kindly search and locate more informative video articles and images that match your interests.

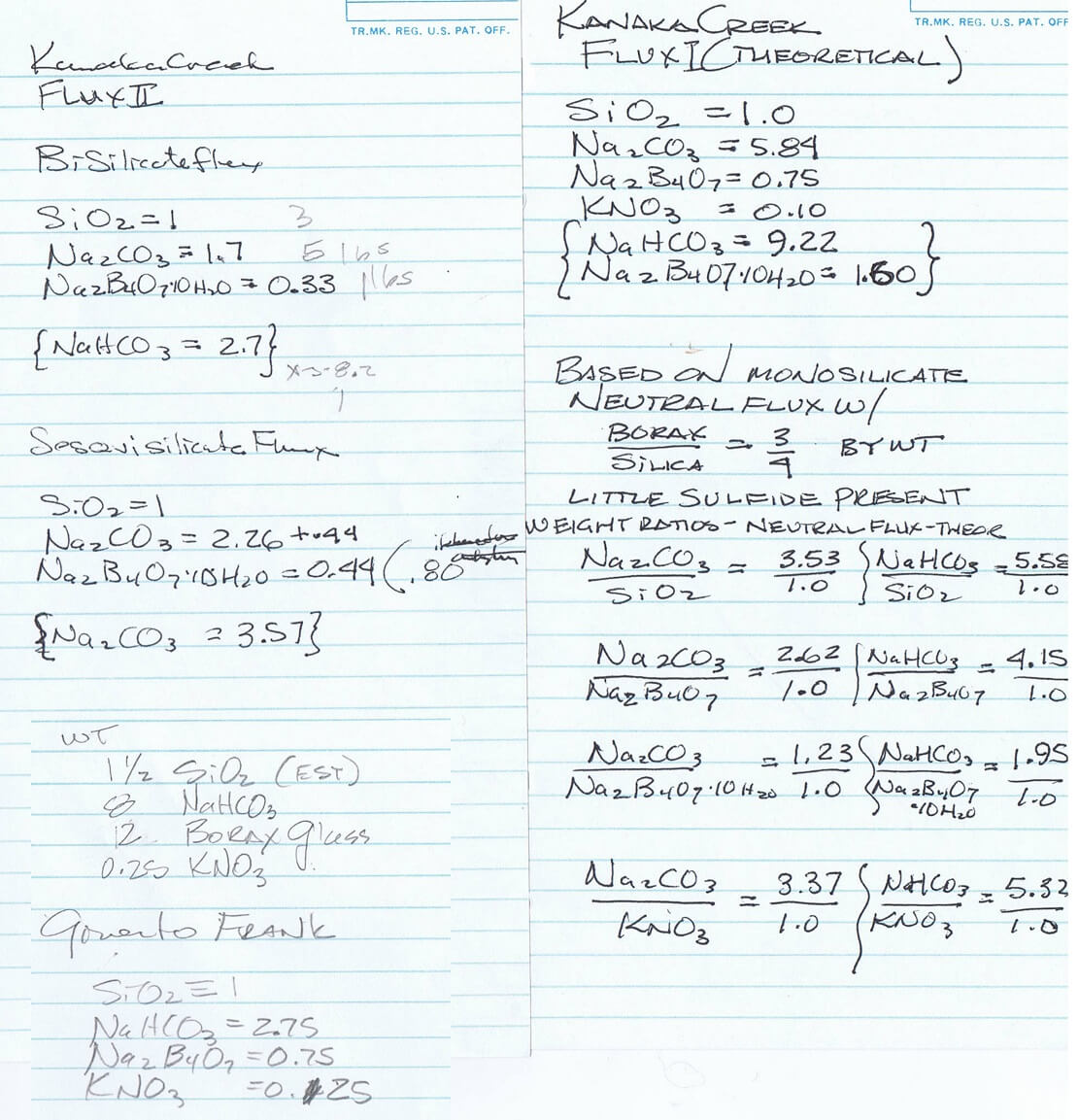

Gold Smelting Flux Formula. In metal refining a flux is sort of like a cleaning agent because it helps remove impurities from a sample. This corresponds to 18kg flux per kg Fe in the ferric state and 23kg flux per kg Fe in magnetite the usual calcined product and 27 kg flux per kg Fe in the ferrous state haematite Further quantities of this flux are added to remove base metals such as Cu and Ni from dore. To improve the quality of the gold mined gold miners have to refine the gold. Gold smelting flux formula - Wembley Primary School Refining gold from ore or concentrates is done during the smelting process During this process flux is used to dissolve contaminates such as.

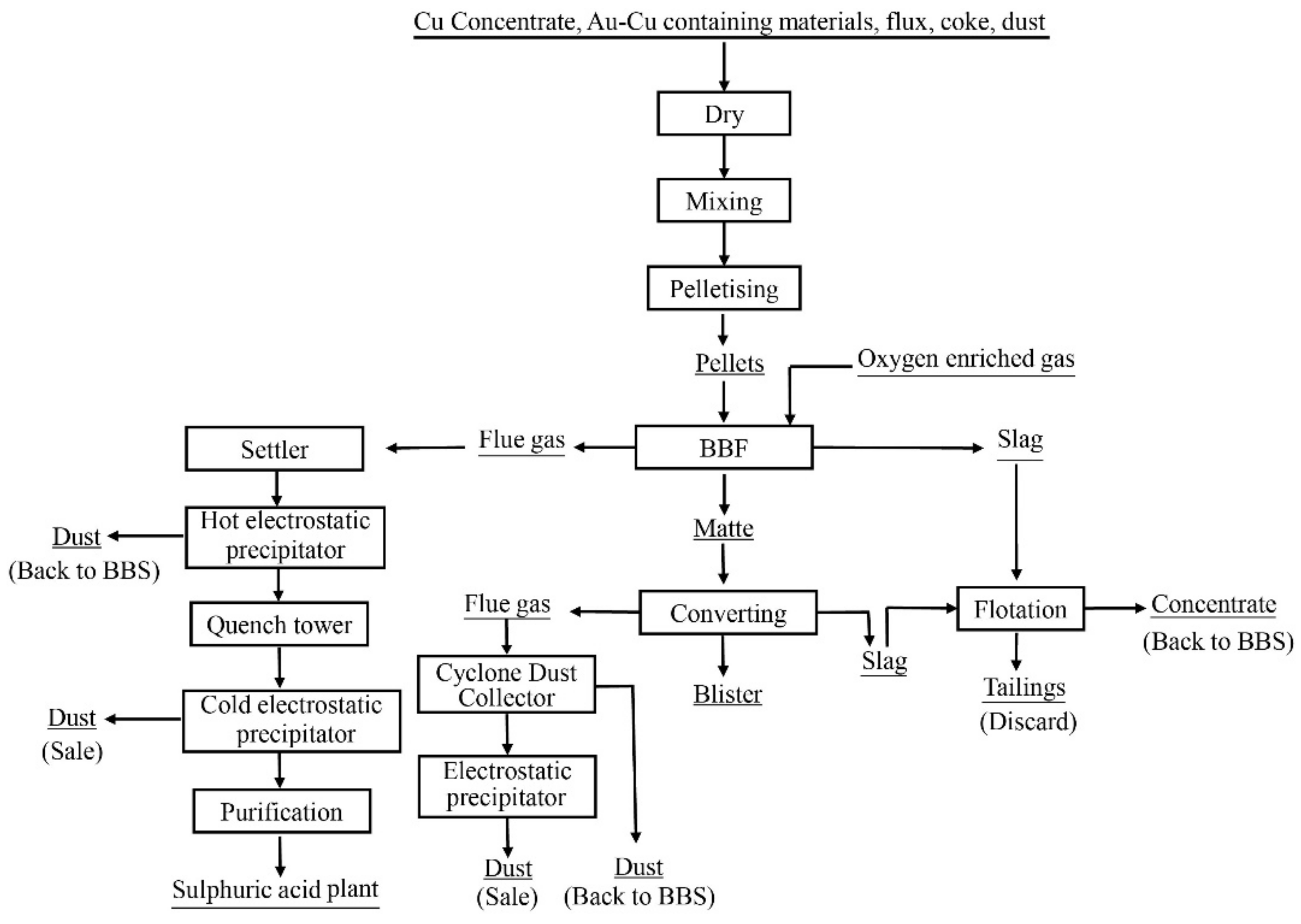

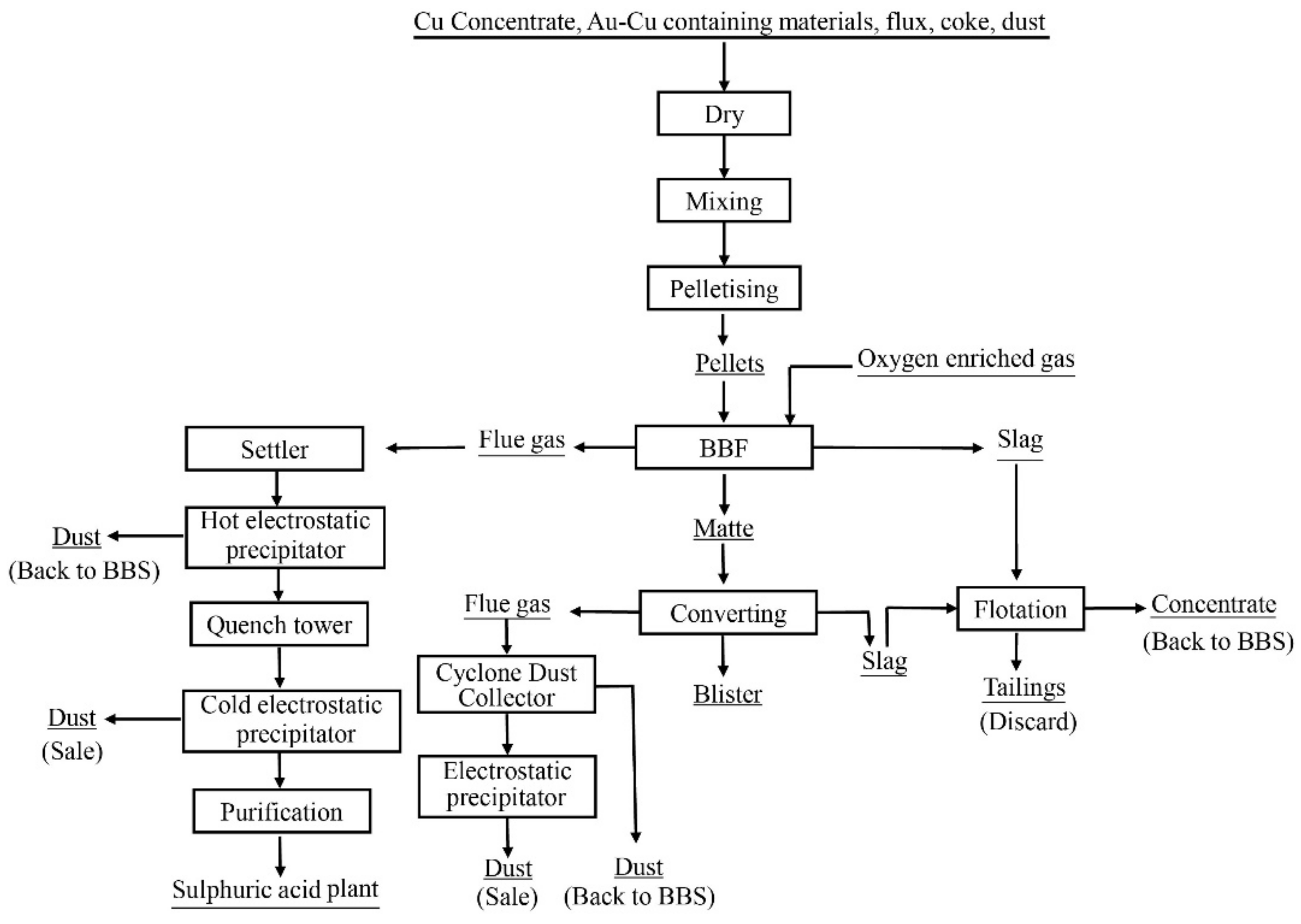

Metals Free Full Text Development Of Bottom Blowing Copper Smelting Technology A Review Html From mdpi.com

Metals Free Full Text Development Of Bottom Blowing Copper Smelting Technology A Review Html From mdpi.com

All it requires is access to a few common minerals and. This corresponds to 18kg flux per kg Fe in the ferric state and 23kg flux per kg Fe in magnetite the usual calcined product and 27 kg flux per kg Fe in the ferrous state haematite Further quantities of this flux are added to remove base metals such as Cu and Ni from dore. Flux is able to react only with the impure metals thereby causing them to form nitrates which can separate out neatly. Measure and weigh 5 oz. With some borax heat and a little know-how its possible to extract pure gold from a sample of ore. This method of gold smelting uses a flux a substance made of borax and sodium carbonate that removes impurities from gold.

It was blown for several hours by foot or hand bellows.

Measure and weigh 10 oz. This is because using borax as the flux reduces the melting point of all the elements in a. Smelting often produces gold to the purity over 90. Gold content ozt gold weight mg x 29166sample weight g Gold Refining Book. Again smelting flux makes metallic oxides easy to eliminate thereby removing another major source of impurity. Gold smelting flux helps us to take advantage of this fact in the smelting process.

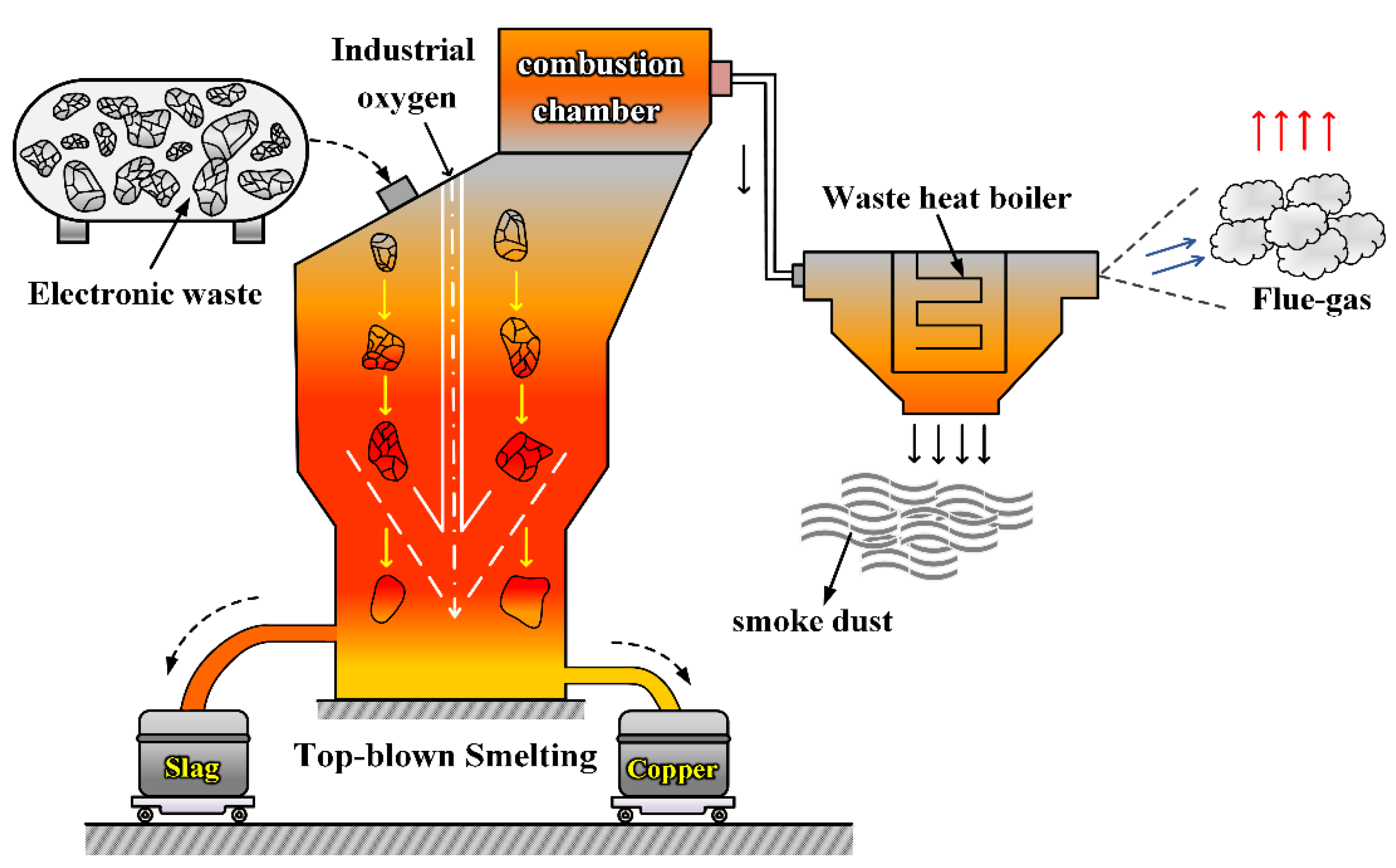

Source: mdpi.com

Source: mdpi.com

Gold smelting flux helps us to take advantage of this fact in the smelting process. Ad Find Deals on flux for smelting gold in Jewelry Making on Amazon. It also plays an important role during the gold refining process as a flux. This will be the oxidizer for the flux. Flux is able to react only with the impure metals thereby.

Source: superbmelt.com

Source: superbmelt.com

Fluorspar - CaF2 Calcium Difluoride Acid Spar For use as an ingredient of assaying flux or flux thinner for melting or smelting gold and other precious metals. 70 Silica Sand 40 parts 3. Smelting gold is accomplished by using high pressure heat and various chemicals to breakdown the ore and melt the gold to separate it from the impurities. Of silica sand 70. Soda Ash 10 parts 4.

Source: pmcsupplies.com

Source: pmcsupplies.com

This goes a long way in making the smelting process more efficient. The first step is to buy a crucible container used for holding the gold as it melts. The gold must be heated to an excess of 1046 degrees Celsius or 2150 degrees Fahrenheit. For example if the fire assay reported 01 mg of gold and the initial weight of sample was 20 g the gold content is 014583 ozt or 454 gt. Soda Ash 10 parts 4.

Source: youtube.com

Source: youtube.com

The first step is to buy a crucible container used for holding the gold as it melts. This is because using borax as the flux reduces the melting point of all the elements in a. A crucible is typically made of clay or graphite carbon. Gold chloride smelting flux Action Mining Mix 6 ounces of the Gold Chloride Smelting Flux formula with the material and place into a crucible Read More Buy Gold and Silver. This method of gold smelting uses a flux a substance made of borax and sodium carbonate that removes impurities from gold.

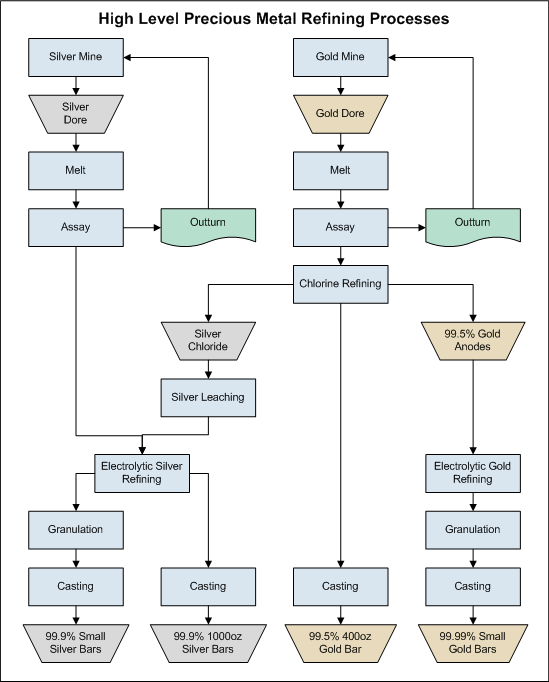

Source: researchgate.net

Source: researchgate.net

A crucible is typically made of clay or graphite carbon. Smelting gold usually involves high-tech and high-cost tools to perform. This is a container created specifically for this process as it can withstand the heat used during the melting process. It enables gold miners to separate impurity materials from pure gold that is desirable in the market. Again smelting flux makes metallic oxides easy to eliminate thereby removing another major source of impurity.

Source: mdpi.com

Source: mdpi.com

Gold smelting flux helps us to take advantage of this fact in the smelting process. Gold chloride smelting flux Action Mining Mix 6 ounces of the Gold Chloride Smelting Flux formula with the material and place into a crucible Read More Buy Gold and Silver. Mostly mining companies do the procedure which sees one material bonded to or released from another in the presence of extreme heat. To improve the quality of the gold mined gold miners have to refine the gold. Of anhydrous borax using the digital scale.

Source: mdpi.com

Source: mdpi.com

Gold chloride smelting flux Action Mining Mix 6 ounces of the Gold Chloride Smelting Flux formula with the material and place into a crucible Read More Buy Gold and Silver. Ad Find Deals on flux for smelting gold in Jewelry Making on Amazon. Assay Fluorspar - used as an ingredient of assaying flux or flux thinner for melting or smelting gold and other precious metals. Flux is able to react only with the impure metals thereby causing them to form nitrates which can separate out neatly. This method of gold smelting uses a flux a substance made of borax and sodium carbonate that removes impurities from gold.

Source: youtube.com

Source: youtube.com

This process takes the smelted gold and using a number of methods. Fluorspar - CaF2 Calcium Difluoride Acid Spar For use as an ingredient of assaying flux or flux thinner for melting or smelting gold and other precious metals. Flux is able to react only with the impure metals thereby. Anhydrous Borax 5 parts 2. Mostly mining companies do the procedure which sees one material bonded to or released from another in the presence of extreme heat.

Source: tf.uni-kiel.de

Source: tf.uni-kiel.de

Measure and weigh 40 oz. This goes a long way in making the smelting process more efficient. This is because using borax as the flux reduces the melting point of all the elements in a. It also plays an important role during the gold refining process as a flux. However prospectors and people at home can smelt their old gold using some simple steps.

Source: tf.uni-kiel.de

Source: tf.uni-kiel.de

A crucible is typically made of clay or graphite carbon. Sodium Nitrate 20 parts Thanks Thetaxidriver. Of sodium carbonate or soda ash. Gold smelting is an important process in the production of gold. Assay Silica FlourSand This product consists of ground silica flour and sand low in moisture with unmatched fineness and a consistency of its particle size.

Source: superbmelt.com

Source: superbmelt.com

I found a formula on the web for smelting gold ore. It also plays an important role during the gold refining process as a flux. Measure and weigh 5 oz. Of anhydrous borax using the digital scale. Soda Ash 10 parts 4.

Source: mdpi.com

Source: mdpi.com

Sodium Nitrate 20 parts Thanks Thetaxidriver. This corresponds to 18kg flux per kg Fe in the ferric state and 23kg flux per kg Fe in magnetite the usual calcined product and 27 kg flux per kg Fe in the ferrous state haematite Further quantities of this flux are added to remove base metals such as Cu and Ni from dore. Of silica sand 70. The gold must be heated to an excess of 1046 degrees Celsius or 2150 degrees Fahrenheit. Gold chloride smelting flux Action Mining Mix 6 ounces of the Gold Chloride Smelting Flux formula with the material and place into a crucible Read More Buy Gold and Silver.

Source: youtube.com

Source: youtube.com

Smelting gold usually involves high-tech and high-cost tools to perform. However prospectors and people at home can smelt their old gold using some simple steps. Gold smelting flux formula - Wembley Primary School Refining gold from ore or concentrates is done during the smelting process During this process flux is used to dissolve contaminates such as. To improve the quality of the gold mined gold miners have to refine the gold. Of silica sand 70.

Source: 911metallurgist.com

Source: 911metallurgist.com

Measure and weigh 40 oz. Gold content ozt gold weight mg x 29166sample weight g Gold Refining Book. This is a container created specifically for this process as it can withstand the heat used during the melting process. Mostly mining companies do the procedure which sees one material bonded to or released from another in the presence of extreme heat. Of sodium carbonate or soda ash.

Source: 911metallurgist.com

Source: 911metallurgist.com

It was blown for several hours by foot or hand bellows. Gold smelting flux formula - Wembley Primary School Refining gold from ore or concentrates is done during the smelting process During this process flux is used to dissolve contaminates such as metal oxides from the gold The flux is added to a crucible with the gold that is then melted in a furnace You can make. This will be the oxidizer for the flux. Gold smelting flux helps us to take advantage of this fact in the smelting process. Gold Smelting Flux Formula.

Source: sciencedirect.com

Source: sciencedirect.com

Ad Find Deals on flux for smelting gold in Jewelry Making on Amazon. Of silica sand 70. A crucible is typically made of clay or graphite carbon. With some borax heat and a little know-how its possible to extract pure gold from a sample of ore. In metal refining a flux is sort of like a cleaning agent because it helps remove impurities from a sample.

Source: in.pinterest.com

Source: in.pinterest.com

Again smelting flux makes metallic oxides easy to eliminate thereby removing another major source of impurity. 70 Silica Sand 40 parts 3. I found a formula on the web for smelting gold ore. Gold smelting flux formula - Wembley Primary School Refining gold from ore or concentrates is done during the smelting process During this process flux is used to dissolve contaminates such as. Gold smelting flux helps us to take advantage of this fact in the smelting process.

Source: pmcsupplies.com

Source: pmcsupplies.com

Sodium Nitrate 20 parts Thanks Thetaxidriver. Smelting gold usually involves high-tech and high-cost tools to perform. To improve the quality of the gold mined gold miners have to refine the gold. You can make flux for gold refining by first obtaining all of the ingredients and then mixing them together in the proper portions. Measure and weigh 5 oz.

This site is an open community for users to do sharing their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site value, please support us by sharing this posts to your preference social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title gold smelting flux formula by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.